Soudotip® Laminar Flow technology is used in this innovatively designed above-standard patented oxygen lance head. It is fully customisable and is an essential tool in improving yields during steel-making using LD converting (BOF).

Entirely the fruit of computer-assisted design and calculations, its production quality and level of technological integration make this blowing nozzle a premium tool for all steel-makers. It is an ideal production tool thanks to its performance and durability. It also helps to accomplish savings of more than 1 € per tonne of steel.

Metallurgical gains

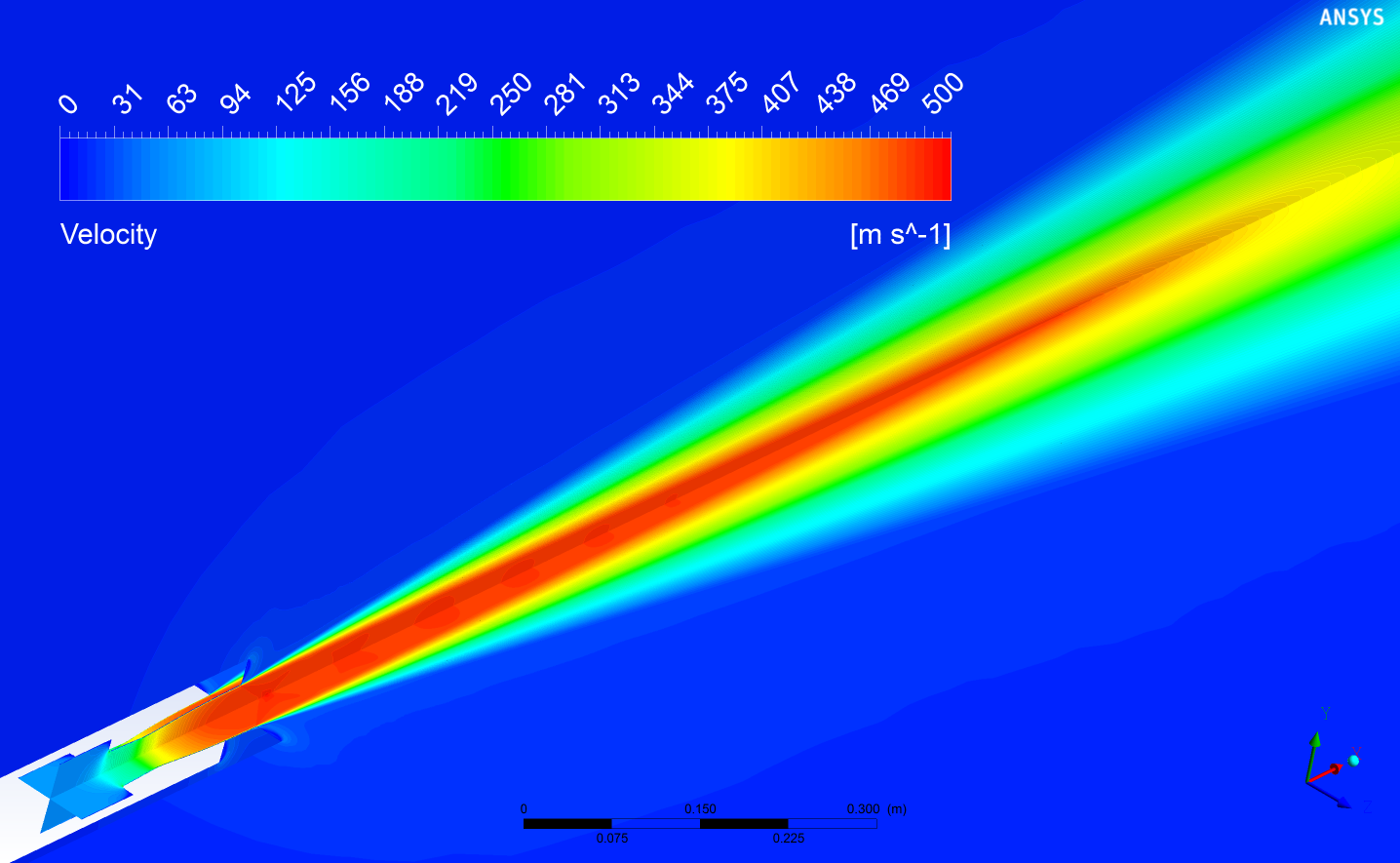

High-density impact coherent oxygen jets boost both metal/slag and metal/metal reactions via superior penetration and agitation.

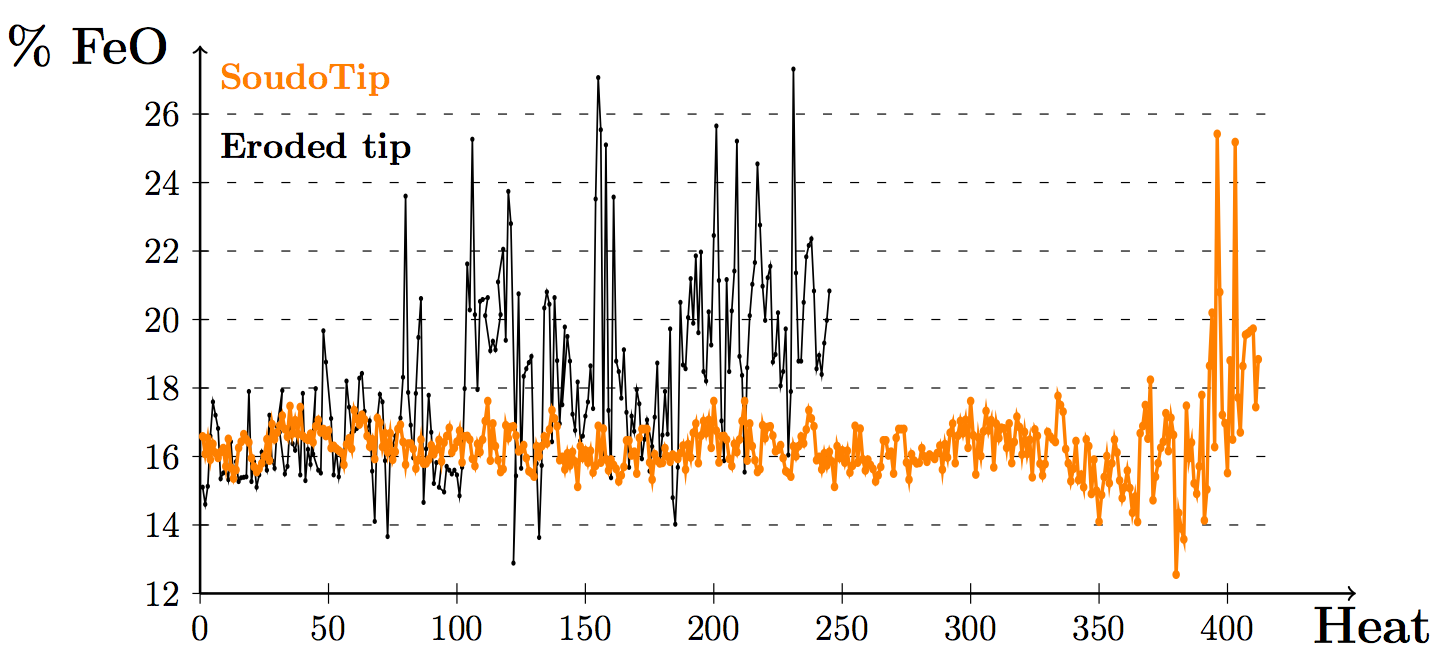

- Reduction of iron loss in slag of 0.8% to 1.2%

- Reduction of dissolved oxygen from 50 to 100 ppm

- Reduction in consumption of killing elements

Customised blowing

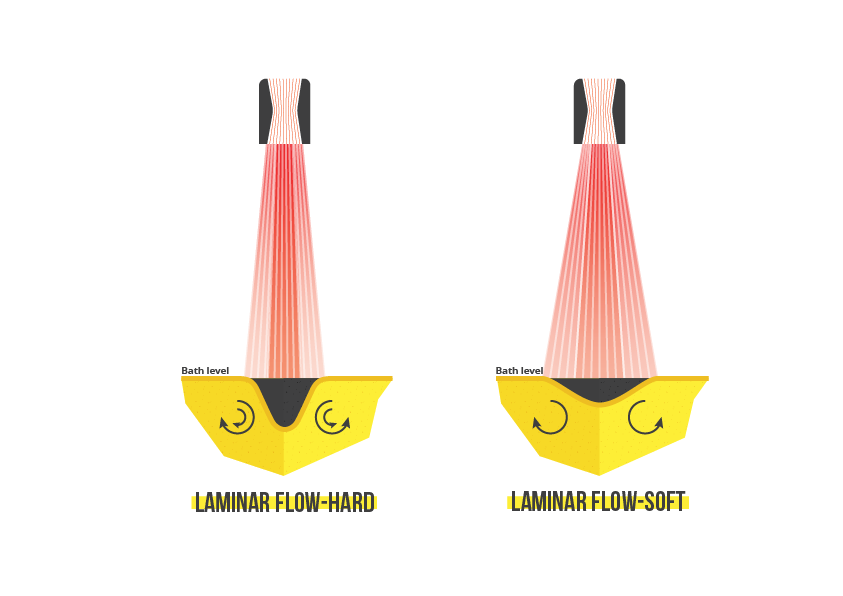

The penetration characteristics of the jets can be customised depending on the needs incurred due to converter configuration and the desired metal-work.

- Hard or soft blowing

- For converters with our without bottom blowing

- Ideal for low phosphorous steel production

Operating stability

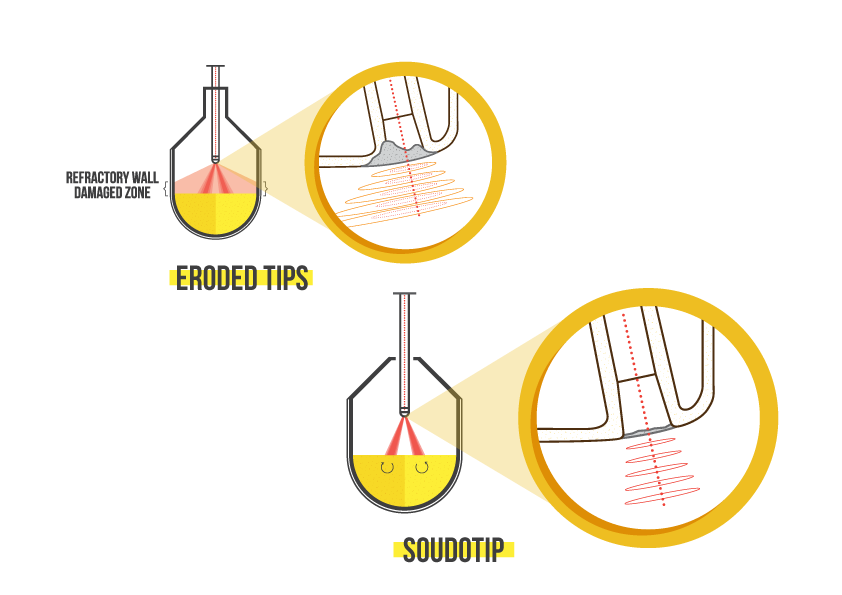

The innovative design allows constant blowing performance throughout the service life of the lance tip and a level of metallurgical replicability that is unequalled.

- Invariable blowing characteristics

- Constant metallurgical yields

- Decrease in re-blowing

Reduced Maintenance

The low-erosion characteristics of the tuyeres make for durable jets, which in turn provides in-depth penetration into the bath and low exposure of the refractory lining, leading to less frequent and more easily planned maintenance.

- Increased service life

- Decrease in projections

- Lower wear of refractory lining