SoudOx® Shielded Flow technology involves a burner combined with supersonic projection of oxygen that can work in different projection modes depending on the desired effect and electric arc furnace (EAF) steel-making phase.

Its highly technical design and manufacturing method provide it with superior blowing and heating power combined with extreme durability. This makes it the essential tool for improving performance in electric arc furnaces.

Metallurgical gains

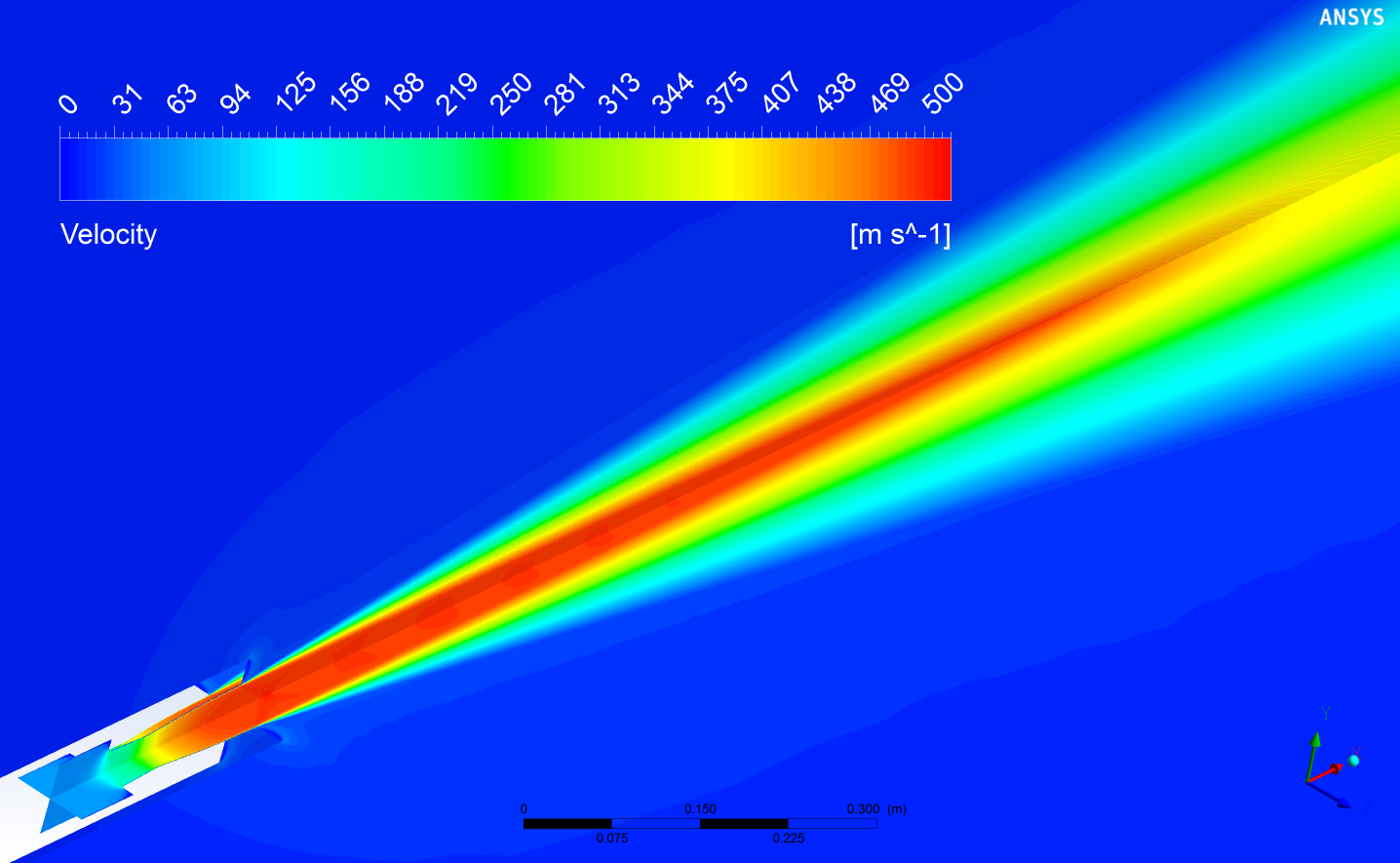

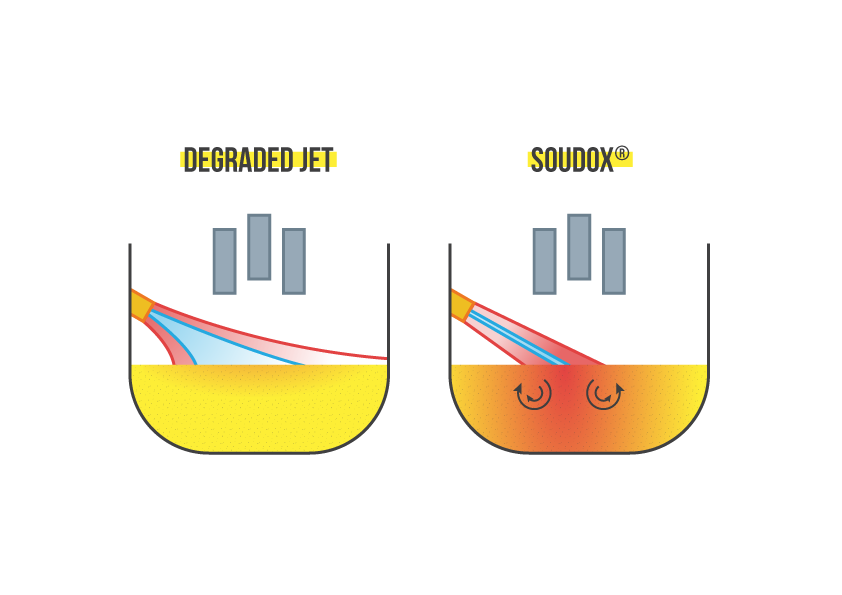

The long or extra-long range coherent supersonic oxygen jet, as a lance alone or in combined oxygen-flame mode, provides greater penetration and agitation.

- Better uniformity of bath composition

- Reduction of iron loss in the slag

- Elimination of unreactive cold zones

Energy gains

The optimised flame, with or without a mixing chamber, possibly accompanied by a penetrative oxygen jet, can produce high heat retention thus shortening the steel-making process.

- Acceleration of scrap metal fusion and decarburization

- Overall decrease in steel-making time

- Reduction in electricity and oxygen consumption

Stability and safety

Its innovative design enables constant and optimal blowing and combustion performance throughout the long-lasting service life of the combined burner.

- Reduction of emissions

- Low head erosion

- Less wear on refractory lining and electrodes

Multiple roles

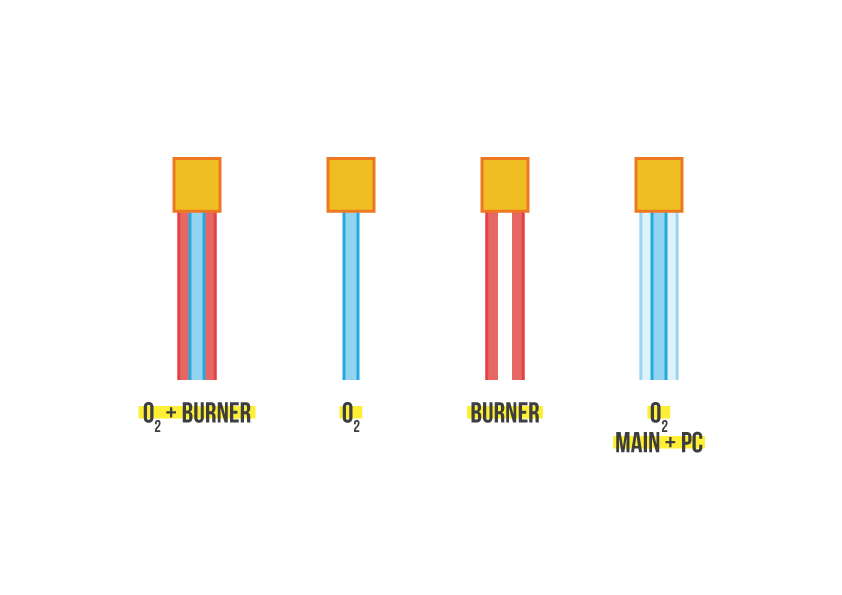

This tool has been designed to operate under several blowing combinations that can be used depending on the steel-making phase and the desired thermo-metallurgical effect.

- Supersonic oxygen and flame for maximum penetration

- Conventional burner for rapid fusion of scrap metal

- O2 main for decarburization with/without O2 peripheral post-combustion