As a company at the cutting edge of oxygen blowing techniques, Soudobeam possesses the whole array of modern engineering resources, from 3D design to numerical simulation, with a view to providing products that meet the most stringent performance and quality standards.

As a partner, Soudobeam proposes continuous technical monitoring in order to permanently provide a product in tune with the distinctive features of each steel-maker.

Our blowing products and techniques, the fruits of innovation implemented by Soudobeam and assisted by collaboration with universities and research centres, regularly benefit from new developments.

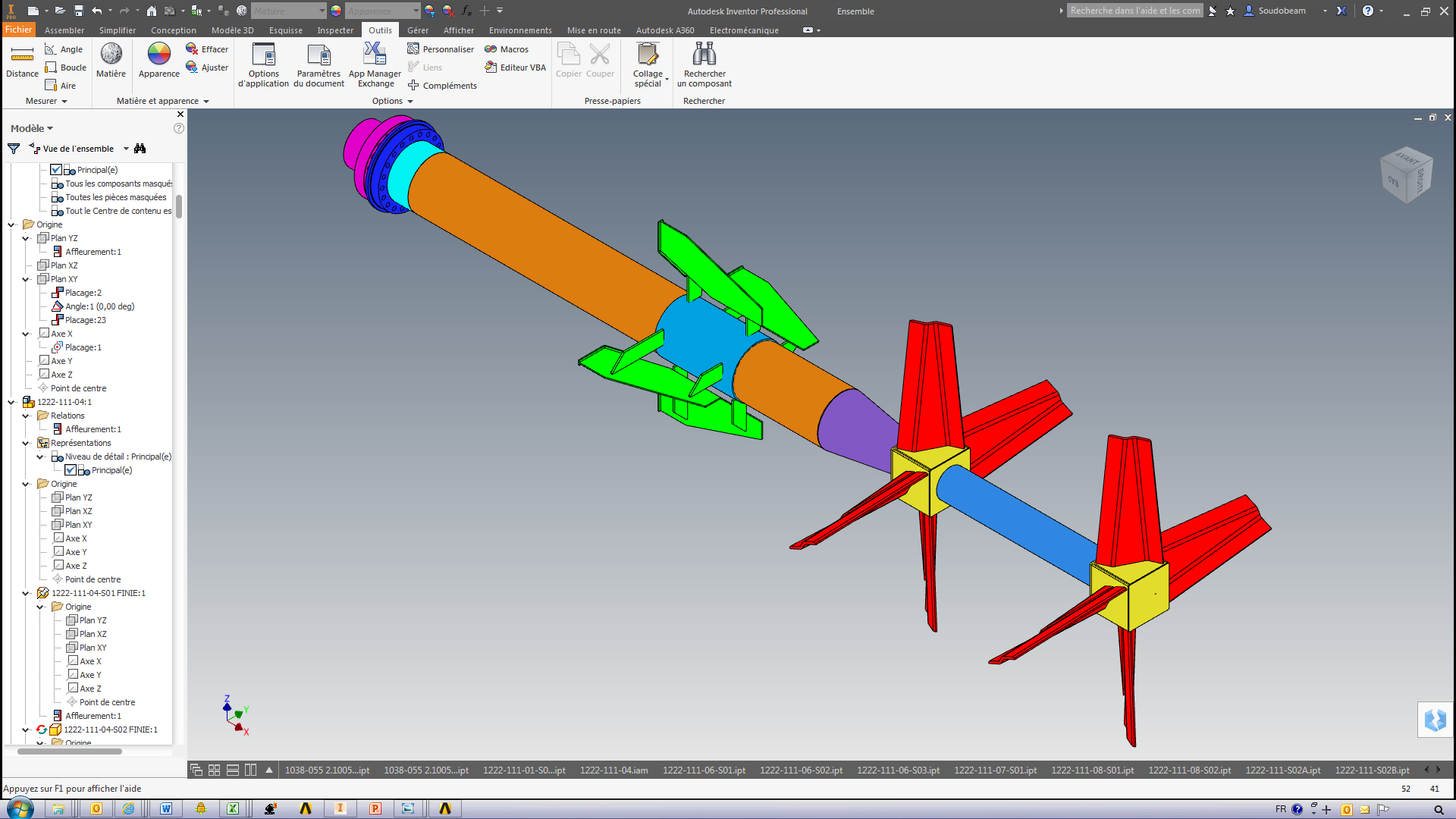

3D design

All our production undergoes studies and computer assisted modelling in order to make the design process more supple and facilitate entry into production.

- Responsive to continual improvement

- A reliable and optimised concept

- The assurance of a compliant product

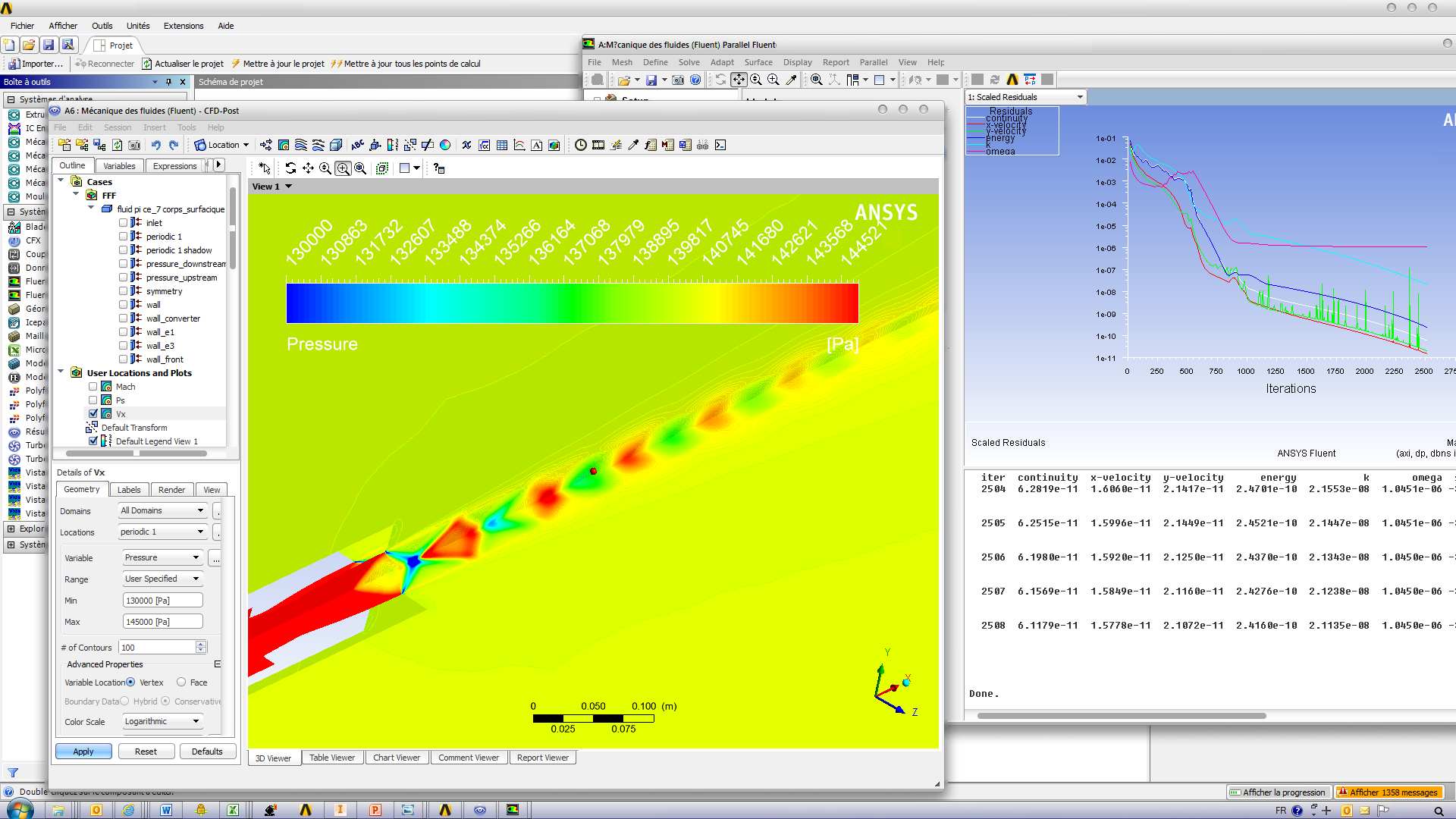

Numerical simulation

In order to provide high-performance blowing characteristics that are adapted to how each steel plant operates, we carry out the calculations for our tuyeres via numerical simulation.

- High quality supersonic jet

- Adjustable blowing hardness

- Continual improvement of project

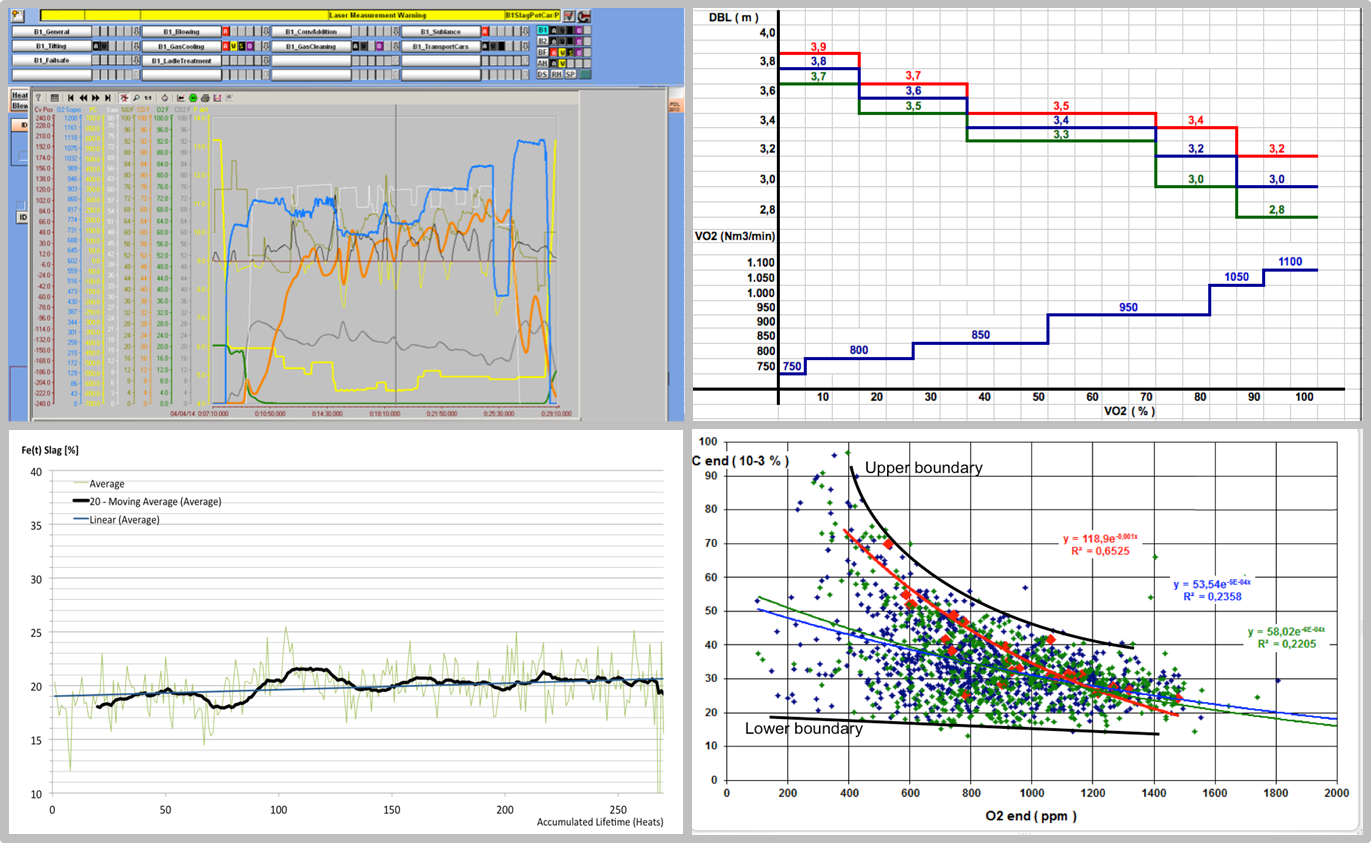

Blowing processes

To help us adapt to the specific nature of each process, we estimate the metallurgical characteristics supplied to determine the most suitable design.

- Blowing adapted to needs

- Metallurgical expertise

- Process support

Continuous technical support

In order to guarantee permanent harmony between our products and steel-makers’ needs, we propose continuous technical monitoring of our blowing equipment.

- Customised guidance

- Support with product use

- On-going development